A Lightweight, Quick-Dry, No-Mess System for Your Decks

Our products are proven to withstand heavy 24/7 foot traffic in all kinds of weather – from the harsh Caribbean sun and salt water to monsoon rains and wide variances of temperatures.

The AGS product system is unique and one-of-kind for your next cruise ship project:

- Features patented interlocking panels that are lightweight and durable, with excellent drainage features.

- Contours and undulations are achieved by using carved, drainable polystyrene foam or layered shaped rubber pads between panels.

- Facilitates deck inspections or servicing needs beneath. For example, a course may be dismantled for deck resurfacing and then re-installed.

- Water drains through our product layers to the ship deck then to the scuppers.

No one else has such a system. You end up with a lightweight, durable, quick-dry, no-mess system.

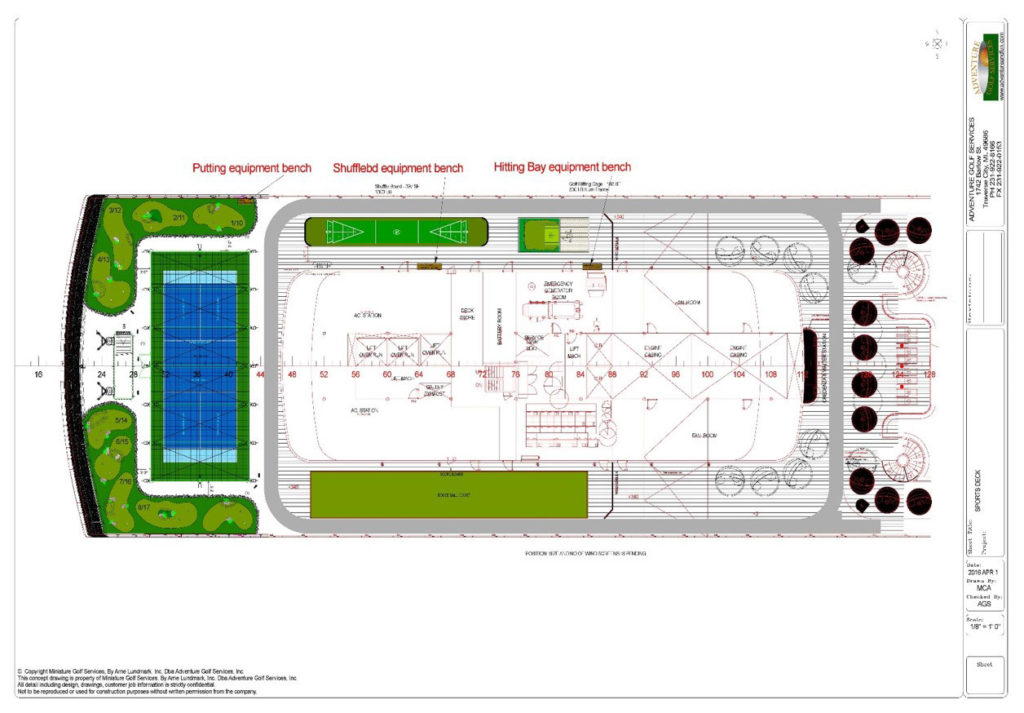

A Pre-Installation walk-through viewing option

If you like, we can pre-build your course in our Traverse City, Michigan USA warehouse to give you the opportunity to see and touch the elements of your course before it’s installed on the ship deck. We can also take you on a walking tour of your course in advance of shipping or installation.

While not fully tacked-down at this stage, you can review it in rough form and have the opportunity to make design changes or shift items before it’s packed up, containerized and shipped to the installation site.

Experienced Fabrication & Installation Team

Each AGS team member averages 8 – 10 years’ experience or more traveling the globe and installing our products in nearly every shipyard around the world.

We’ve installed miniature golf courses and game courts on ship decks in the Bahama Islands, Caribbean Sea ports, domestically in the U.S. and Canada, as well as several countries, ports and shipyards in Europe, the United Kingdom and Asia.

Our logistical and onsite experience at ports and shipyards has been invaluable in keeping installations on time and on budget. In other words, we know how to get in and out of yards and ports efficiently.

To increase the efficiency of miniature golf course installation, we can send in advance a CAD file weld-plan along with pre-fabricated anchor brackets, so the yard can tack down on deck before our team arrives. If you prefer, we can send a technician to oversee and supervise this process.

Lead Times

Design, fabrication and installation lead times vary, depending upon the product and yard location.

Design: May take a few days to a couple of months depending upon the complexities and client involvement.

Fabrication: It is important to realize that theme elements used in miniature golf course designs, such as dragons, sea creatures, lighthouses, traffic lights, jungle trees, rocket ships, wild west huts and other elements, require the longest lead times to build and receive – often three to six months!

Installation: Some miniature golf courses are heavily themed and may require contours and undulations underneath our panel system. Such complex, heavily-themed contoured courses may take upwards of 10+ days to install once our team arrives.

At the other end of the spectrum, a small putting green or single bocce ball game court might be a one or two-day installation. Regardless, our team is experienced and we always try to come in on time and on budget.

Let’s Get Started! Tell us what product you’re looking for or ask to see what’s possible. Send us your Deck Plan in a .dwg (CAD) file and we can begin the process!